Bespoke Test Connection Challenge

Warwick Test Supplies Bespoke Test Connection

Here at Warwick Test Supplies we are often asked for advice regarding test connection issues and connection challenges faced by clients. With over a quarter of a century of test connection knowledge we can normally identify a connection product and method that will suit an application. However there are times when there just isn't anything on the market or products just don't fit the bill for the application due to form, fit or working practices. This can also be the case with a product that partially solves the issue but is just a work around and not very efficient.

That's where our custom and bespoke design and production service comes into its own and is the best way to solve a connection challenge.

Why Is Bespoke Best?

- You gain a solution that is designed specifically for its application and use. This improves efficiency and makes connection and testing workflow simpler and faster;

- Test combinations can be designed into the solution to reduce the number of tests, making them concurrent, saving time and gaining efficiency;

- The solution will have longevity designed in with guaranteed performance lifecycle enabling lifetime planning and costs to be known upfront;

- No more 'botching' a work around that suffers reliability and quality issues.

We also don't believe in forcing minimum order quantities on clients, so it doesn't matter whether the requirement is for a single one off connection or a production run. Have a look at the case study for a one off test clip connection below.

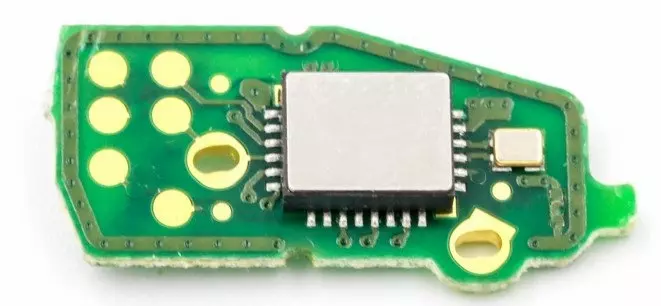

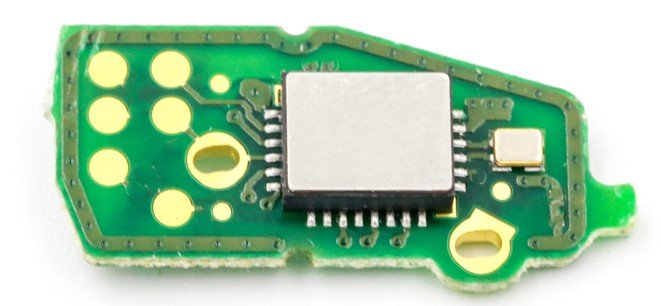

Case study - IC Footprint Mount

A client had developed and manufactured a bespoke Integrated Circuit (IC). The IC footprint was a non-standard surface mount package with a fine leg pitch. There was a requirement to be able to test the IC whilst in circuit mounted on a double sided PCB surrounded by other close components. There were no 'off the shelf' IC test clips that fitted the bill and other products to make simultaneous connection to pins were deemed unsuitable.

Working closely together to fully identify the requirements and specification Warwick Test Supplies designed a 3D model of a bespoke test clip to prove the concept, before manufacturing the product.

I have a connection challenge - What is the process?

If you have a connection issue requirement then the first step is to get in touch with us and discuss your challenge. We then follow this process:

- Establish the need for a bespoke solution and agree a specification;

- Complete a design and manufacturing agreement which details the specification, any phases, milestones and key completion criteria;

- Design the connection and produce a 3D model to enable a full visualisation of a finished product;

- Design evaluation and make any modifications required;

- Produce a prototypes if required and sign the design off;

- Production, final quality testing and delivery.

If you would like to find out more about our bespoke connection production capabilities or would like to discuss your own connection challenge then please contact us here...